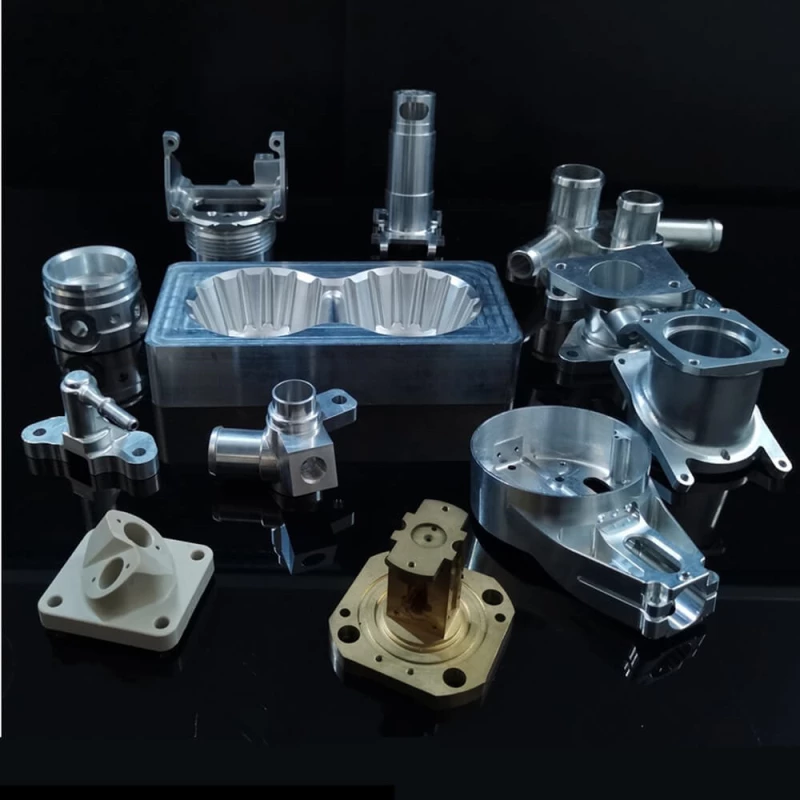

How Rapid Machining Works – At Brightstar, over 50 high precision CNC mills, lathes, liner cutting, silk print machines, and surface grinding machines help us deliver custom CNC machining for many industries. We deliver rapid prototyping solutions.

3, 4 and 5 axis machines are available at Brightstar. A massive range of materials both metal and plastics are available at Brightstar, The available materials in Brightstar for CNC machining are a wide range of metal and plastic, including aluminum, brass, copper, bronze, stainless steel, steel, plastic (ABS, PA, PE, PP, PC, ACRYLIC, PMMA, PEEK)..., etc

Surface treatment for CNC machining parts or prototypes contains transparent / color anodizing, Painting, Powder coating;Sand blasting, Laser carving, Silk screening;Nickel plated, chrome, Galvanized, Silver / gold plating, Black oxide coating, polishing.... etc.

Advantages Of Precision CNC Machining

- Fast and repeatable for low volume manufacturing

- CNC prototypes deliver on precise and high tolerance specifications

- Wide range of production and rapid prototype manufacturing materials

- Rapid machining offers great surface finishing

CNC Machined parts are precise and have high tolerance specifications; the process itself is fast and a wide range of materials can be used. Due to these qualities, CNC Machining is popular choice in the automotive industry

Custom CNC Machining Is Used For

Precision CNC machining parts and rapid prototyping, metal parts, performance plastics, and low-mid volume rapid machining production runs. When it comes to China CNC machining or custom CNC machining in general, our approach is: provide highly flexible rapid low volume manufacturing solutions that deliver superior parts, fast.

Follow us on Facebook or LinkedIn for daily tips, advice, trends, and opinions on rapid manufacturing. For fast parts, click below to start.

Our core focus is rapid prototypes that start with an MOQ of 1 and low volume manufacturing solutions up to 100,000 parts. We don’t box you into rapid manufacturing solutions that are good for us. Instead we work with you to create bespoke solutions that work for your project needs. At Brightstar Prototypes, we make things for you…FAST!

To start your free project review talk to our rapid projects teams today.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.